Las 5 mejores herramientas eléctricas para pequeñas carpinterías

Índice

- 1. Sierra de mesa - El caballo de batalla del taller

- 2. Fresadora + mesa de fresado: versatilidad en un paquete pequeño

- 3. Sierra ingletadora - Cortes transversales rápidos y precisos

- 4. Combo taladro/atornillador + atornillador de impacto - Lo esencial para el día a día

- 5. Sistema de recogida de polvo: no se lo salte

- Herramienta extra: Lijadora Orbital Aleatoria - Para Acabados Impecables

- Preguntas frecuentes

Dirigir un pequeño taller de carpintería significa equilibrar espacio, presupuesto y eficacia. Cada máquina que incorpore tiene que ganarse su sitio ofreciendo precisión, versatilidad y durabilidad a largo plazo. La buena noticia: no necesita un almacén lleno de herramientas eléctricas para realizar un trabajo de calidad profesional. Con la configuración básica adecuada, puede encargarse de todo, desde la fabricación de muebles hasta proyectos personalizados, sin perder tiempo ni espacio.

Éstas son las cinco herramientas eléctricas más recomendables para los pequeños talleres de carpintería:

1. Sierra de mesa - El caballo de batalla del taller

Si sólo puede invertir en una herramienta eléctrica importante, que sea una sierra de mesa. Una buena sierra de mesa puede realizar cortes al hilo, cortes transversales, ranuras e incluso ensamblajes precisos. Para tiendas pequeñas, busque:

- Tamaño compacto con un soporte o armario resistente.

- Un sistema de vallas que se bloquea a escuadra y se mantiene preciso.

- Compatibilidad con la recogida de polvo para mantener limpio el espacio de trabajo.

Una hoja de calidad marca la diferencia, así que utilice las hojas de calidad superior de Amana Tool para obtener cortes suaves y sin quemaduras.

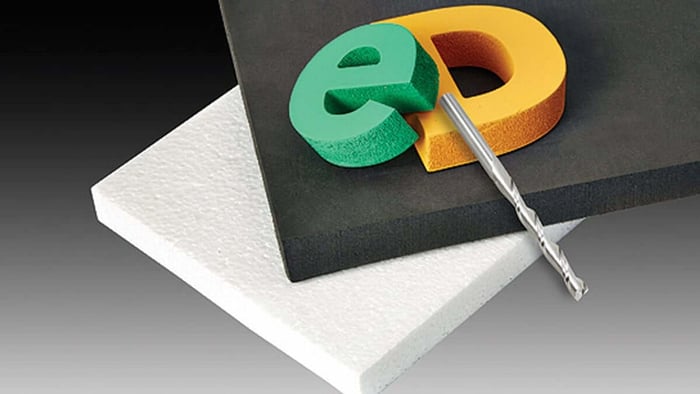

2. Fresadora + mesa de fresado: versatilidad en un paquete pequeño

Ningún taller está completo sin una fresadora. Ya sea manual o en una mesa de fresado, las fresadoras destacan en el perfilado de cantos, el ensamblaje y el trabajo con plantillas. Para los profesionales, la OF 1400 de Festool es una de las favoritas: pesa menos de 10 libras y tiene una potencia de 1400 vatios. / 2,25 CV

Combínela con una pequeña mesa de fresado y tendrá una máquina de carpintería, una tupí alternativa y una estación de acabado de bordes todo en uno.

3. Sierra ingletadora - Cortes transversales rápidos y precisos

Para cortar material a medida con rapidez y precisión, no hay nada mejor que una sierra ingletadora compuesta deslizante. Ahorra tiempo al descomponer tablas, recortar ángulos o cortar molduras de corona. Características clave a tener en cuenta:

- Acción deslizante para cortes transversales anchos.

- Topes positivos para ángulos comunes.

- Un soporte compacto o una estación montada en la pared para ahorrar espacio.

Consejo profesional: reserve la sierra de mesa para los cortes de precisión y deje que la sierra ingletadora se encargue de las dimensiones aproximadas para prolongar la vida útil de la hoja.

4. Combo taladro/atornillador + atornillador de impacto - Lo esencial para el día a día

En un taller pequeño, necesitará constantemente un taladro atornillador y un atornillador de percusión para la instalación de herrajes, la construcción de plantillas y los proyectos de taller. Un kit combinado inalámbrico le ofrece:

- Potencia y par tanto para taladrar como para hincar.

- Cambios rápidos de brocas y baterías de larga duración.

- Flexibilidad para moverse por el taller (o la obra) sin cables.

Tenga a mano un juego de brocas y avellanadores de calidad para realizar orificios limpios y precisos en maderas duras.

5. Sistema de recogida de polvo: no se lo salte

Puede que el polvo no parezca una "herramienta eléctrica", pero es una de las inversiones más importantes que hará. Incluso un taller pequeño necesita un colector de polvo específico o un aspirador de taller de gran capacidad. Entre sus ventajas se incluyen:

- Aire más limpio y condiciones de trabajo más seguras.

- Mayor vida útil de la herramienta gracias a la reducción de las incrustaciones.

- Menos tiempo dedicado a la limpieza al final del día.

Empiece con una unidad móvil o instale un sistema compacto montado en la pared. Mejórelo a medida que su tienda crezca: sus pulmones se lo agradecerán.

Herramienta extra: Lijadora Orbital Aleatoria - Para Acabados Impecables

El corte y el ensamblaje acaparan toda la atención, pero el acabado es lo que hace que un proyecto funcione. Una lijadora orbital aleatoria es la herramienta ideal para preparar las superficies de madera antes de aplicar el tinte, la pintura o la capa transparente. A diferencia de las lijadoras de hoja estándar, el movimiento orbital aleatorio evita las marcas de remolino al tiempo que elimina el material de forma rápida y uniforme.

Esta herramienta brilla en:

- Construcción de muebles: alisado de tableros, partes de sillas y cantos.

- Ebanistería: preparación de marcos y paneles antes del acabado.

- Pequeños proyectos: dar un toque profesional a tablas de cortar, carteles y cajas.

Combínela con discos de lijado de alta calidad de varios granos (80-220 y superiores) para pasar sin problemas del perfilado al acabado final. Una lijadora con aspiración de polvo integrada (o un puerto para conectarla a su sistema de aspiración) también mantendrá su espacio de trabajo más limpio y saludable.

Preguntas frecuentes

¿Con qué herramientas eléctricas debería empezar todo pequeño taller de carpintería?

Lo esencial es una sierra de mesa, una fresadora con mesa para fresar, una sierra ingletadora, una combinación de taladro y atornillador y un sistema de recogida de polvo. Estos cinco equipos cubren la mayoría de las tareas de corte, ensamblaje y acabado sin saturar el taller.

¿Cómo elegir la sierra de mesa adecuada para un taller pequeño?

Busque una sierra compacta con un sistema de guía robusto, dispositivos de seguridad fiables y una buena recogida de polvo. Las sierras de mesa híbridas y para contratistas suelen ofrecer un buen equilibrio entre potencia y tamaño para los talleres más pequeños.

¿Merece la pena una mesa de fresado si ya tengo una fresadora de mano?

Sí. Una mesa para fresadora convierte su fresadora de mano en una estación de precisión para ensamblar y dar forma. Proporciona estabilidad para trabajos detallados, un manejo más seguro para piezas pequeñas y una mayor versatilidad en general.

¿Qué tamaño de colector de polvo es mejor para un pequeño taller de carpintería?

Un aspirador portátil de 1-2 CV o un aspirador de taller de gran capacidad suelen ser suficientes. Si utiliza varias máquinas a la vez o produce mucho polvo fino, un sistema montado en la pared o de tipo bidón puede ser una mejor inversión.