CNC para escenógrafos: Foamboard, Panels, & Props Made Easy

Índice

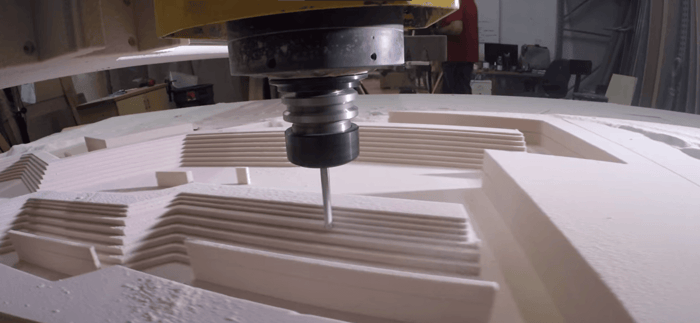

Las producciones escénicas, cinematográficas y televisivas exigen decorados ligeros, duraderos y rápidos de producir. Para muchos talleres de escenografía, las fresadoras CNC se han convertido en una herramienta esencial que sustituye a las horas de corte manual con resultados precisos y repetibles en paneles de madera, cartón pluma y materiales compuestos. Los teatros de Broadway, los estudios de televisión y las producciones en gira confían en el CNC para realizar diseños ambiciosos en plazos ajustados sin salirse del presupuesto.

Por qué el CNC es importante para la escenografía

- Rapidez: los pisos, el atrezzo y los telones de fondo más complicados pueden cortarse en minutos en lugar de horas.

- Precisión: Los archivos digitales garantizan formas consistentes, sustituciones fáciles y revisiones rápidas cuando los directores solicitan cambios.

- Versatilidad: Desde esculturas de cartón pluma hasta planos de madera contrachapada, el CNC puede manejar una amplia gama de materiales escénicos.

- Ahorro de costes: La reducción del tiempo de mano de obra y del material desperdiciado hacen que el CNC sea una inversión que se amortiza rápidamente para los talleres con mucho trabajo.

Materiales comunes en la construcción escénica

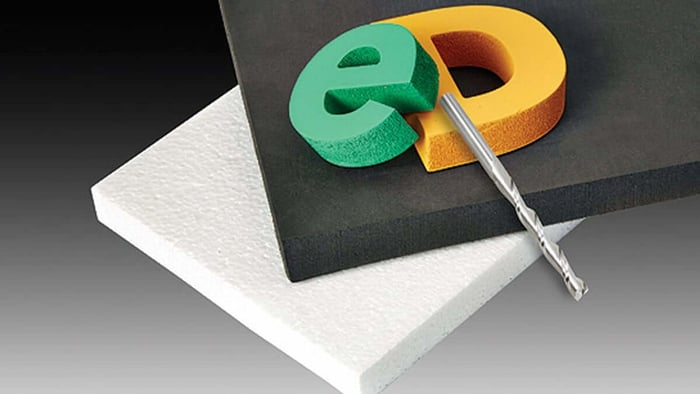

- Tablero de espuma (XPS, EPS): Se utiliza para texturas esculpidas, paredes escénicas y atrezo ligero. Las herramientas CNC para espuma con revestimiento de nitruro de titanio (TiN ) permiten realizar cortes profundos con bordes lisos y menos pasadas.

- Tableros contrachapados y MDF: La columna vertebral de pisos y estructuras. Las brocas de compresión proporcionan bordes superiores e inferiores limpios, minimizando el trabajo de acabado antes de pintar.

- Tablero de señalización de PVC y HDU: Popular para puntales duraderos y señalización reutilizable. Las brocas recubiertas de ZrN evitan las vibraciones y reducen la acumulación de calor al fresar plásticos.

- Acrílicos y policarbonato: Ideal para ventanas de escenarios, cajas de luz o señalización. El mecanizado en O proporciona bordes lisos y pulidos sin fundir.

- Aluminio y metales finos: Utilizados ocasionalmente para estructuras escénicas y atrezo. Las herramientas de un solo filo o recubiertas de ZrN ayudan a reducir el calor y prolongan la vida útil de la herramienta.

Las mejores brocas CNC para escenógrafos

- Puntas para cortar espuma (recubiertas de TiN): Diseñadas para cortar espumas gruesas con precisión y velocidad. La expulsión suave de la viruta mantiene los cortes limpios y evita el desgaste de la herramienta.

- Brocas de compresión: Perfectas para contrachapados planos y laminados, dejando los bordes nítidos listos para el acabado.

- Puntas de corte: Imprescindibles cuando se necesita una superficie superior impecable en paneles que se van a pintar o chapar.

- Puntas de flauta en O: Ideales para plásticos y compuestos ligeros utilizados en atrezzo y señalización.

- Herramientas de inserción: Rentable para talleres escénicos de gran volumen, ya que permite sustituir cuchillas en lugar de brocas enteras.

- Puntas de bola: Ideal para tallar piedra, ladrillo o texturas de grano de madera en espuma para acabados escénicos realistas.

- Puntas de grabado: Útiles para letras finas o detalles decorativos en accesorios y señalización.

- Bits de alcance ampliado: Fundamental para cortar bloques de espuma de gran tamaño o paneles más profundos sin comprometer la precisión.

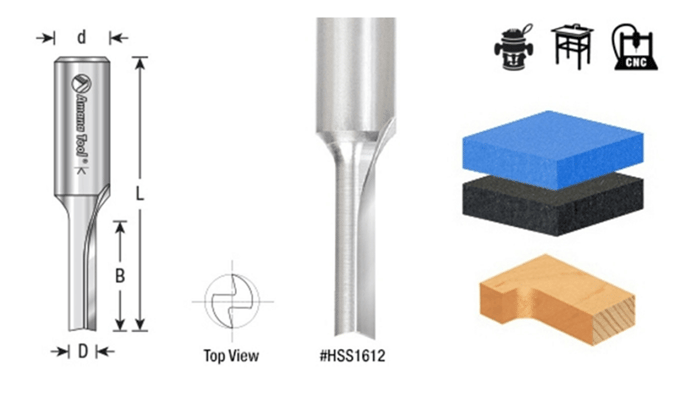

Fresas en espiral de 4 hélices para un mayor alcance

El revestimiento de nitruro de titanio (TiN) aumenta la resistencia y la durabilidad

Flexibilidad de diseño con CNC

- Corte intrincadas formas de ventanas y puertas directamente en planos escénicos.

- Tallar texturas de espuma en 3D como ladrillo, piedra o motivos decorativos.

- Duplique paneles y utilería con precisión, especialmente útil para producciones itinerantes que requieren reemplazos.

- Combine materiales (madera, espuma, plásticos) en un mismo diseño para obtener efectos dimensionales por capas.

Consejos para empezar

- Utilice brocas de mayor diámetro para los planos y paneles de gran tamaño para ahorrar tiempo de corte.

- En el caso de la espuma, haga coincidir la geometría de las estrías para evitar que se rompan o se fundan.

- Ajuste la profundidad de corte al grosor del material: el fresado de una pasada ahorra tiempo y reduce los errores.

- Tenga en cuenta la recogida de polvo: el MDF y la espuma producen polvo cargado de electricidad estática que puede interferir en el acabado.

- Utilice velocidades de husillo más lentas con plásticos y espumas para evitar que se fundan o que queden bordes ásperos.

- Gire entre las brocas de desbaste y las de acabado para prolongar la vida útil de la herramienta y mejorar la calidad del corte.

Dé vida a sus ideas escénicas con CNC

Ya sea que esté construyendo pisos de escenario para teatro o utilería compleja para cine y TV, las brocas CNC adecuadas hacen que la construcción escénica sea más rápida, segura y precisa. Desde herramientas para espuma hasta brocas de compresión, ToolsToday ofrece soluciones CNC de calidad profesional para que su producción funcione sin problemas. Y cuando el espectáculo debe continuar, un utillaje fiable significa que se mantiene a tiempo, dentro del presupuesto y listo para el siguiente cambio de escena.