Corte de fibra de carbono con CNC: consejos, seguridad y selección de brocas

Índice

- ¿Qué es la fibra de carbono?

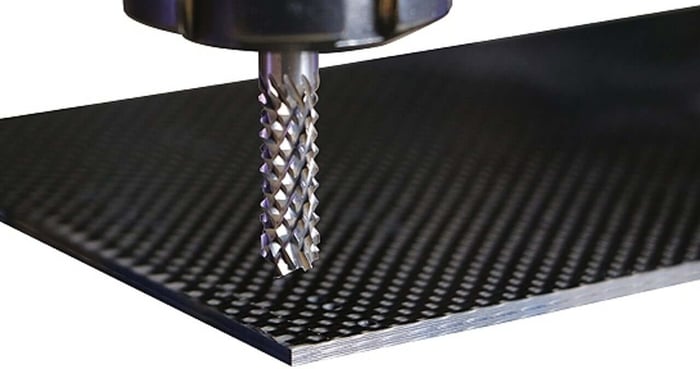

- Amana® Punta de fresa de metal duro macizo con patrón de diamante, brocas para fresadora para corte de materiales compuestos

- Dónde se utiliza la fibra de carbono

- Desafíos del mecanizado CNC de fibra de carbono

- La seguridad ante todo

- Cómo elegir las fresas adecuadas

- Carburo sólido Spektra™ Extreme Tool Life Recubierto de Carbono Espiral Grafito y Fibra de Carbono Brocas para Fresar

- Consejos de corte para resultados limpios

- Ejemplo de configuración

- Acabado y limpieza

- Conclusión

- Preguntas frecuentes

La fibra de carbono es uno de los materiales más impresionantes que se pueden mecanizar: resistente, ligero y elegante. Pero también es uno de los más delicados. Cualquiera que haya intentado cortarla con una fresadora CNC sabe que puede dañar las brocas, deshilachar los bordes y llenar el taller de polvo peligroso si no se tiene cuidado.

La buena noticia: con la configuración adecuada, equipo de protección y las fresas de composite Amana Tool®, puede producir bordes limpios y resultados de calidad profesional, manteniendo su equipo - y sus pulmones - a salvo.

¿Qué es la fibra de carbono?

La fibra de carbono no es un trozo sólido de carbono. Es un compuesto que se obtiene entretejiendo finas hebras de carbono e incrustándolas en una resina, normalmente epoxi. Una vez curada, forma una lámina rígida increíblemente ligera y resistente.

Al tratarse de un compuesto, cortar fibra de carbono es más parecido a mecanizar capas de tejido y pegamento endurecido a la vez. La resina puede fundirse o astillarse si se sobrecalienta, mientras que las fibras pueden deshilacharse o delaminarse si se cortan de forma incorrecta.

- Relación resistencia/peso muy elevada

- Excelente rigidez y resistencia a la fatiga

- Resistencia térmica y química

- Conductor eléctrico

Dónde se utiliza la fibra de carbono

La fibra de carbono aparece en cualquier lugar donde la resistencia y el bajo peso sean importantes:

- Automoción y deportes de motor: paneles de carrocería, soportes, salpicaderos

- Aeroespacial y vehículos aéreos no tripulados: bastidores de drones, componentes interiores

- Marina: hélices, refuerzos del casco

- Material deportivo: bicicletas, palas, raquetas

- Dispositivos industriales y médicos

- Fabricación a medida y proyectos "maker

A medida que aumenta la capacidad de las fresadoras CNC, hasta los talleres más pequeños empiezan a trabajar con planchas de fibra de carbono para piezas personalizadas, prototipos y construcciones artísticas.

Desafíos del mecanizado CNC de fibra de carbono

La fibra de carbono es notoriamente abrasiva. Desgasta las brocas de carburo estándar a una velocidad alarmante, produciendo bordes ásperos y polvo en suspensión que no solo es sucio, sino también conductor y peligroso.

Entre las cuestiones clave figuran:

- Abrasividad: Desafila rápidamente las herramientas de corte estándar

- Delaminación: Las capas pueden pelarse o deshilacharse si la velocidad de avance o la geometría de la broca son incorrectas.

- Acumulación de calor: Puede quemar o debilitar la resina

- Peligros del polvo: Las partículas finas de carbono conductor pueden dañar los aparatos electrónicos y los pulmones

Por eso, el mecanizado de fibra de carbono requiere brocas especializadas para el corte de compuestos y estrictas precauciones de seguridad. Los polímeros reforzados con fibra de carbono (CFRP) requieren un sustrato de metal duro muy resistente a la abrasión, un acanalado generoso y una zona de impacto que no sólo "rompa" las duras fibras de carbono, sino que también mantenga bajo el calor.

La seguridad ante todo

Antes de cortar fibra de carbono, asegúrese de que la configuración de su taller le protege tanto a usted como a su equipo.

1. Recogida de polvo

Utilice un sistema completo de recogida de polvo o una zapata de aspiración directamente en el punto de corte. El polvo de carbón se esparce fácilmente y puede cortocircuitar los componentes electrónicos del CNC si se deposita en el interior de la máquina.

2. Protección respiratoria

Un respirador P100 es esencial. Las máscaras antipolvo normales no detienen las partículas ultrafinas que se liberan durante el corte.

3. Protección de ojos y piel

Llevar gafas y guantes herméticos. Las fibras pueden irritar la piel y los ojos si se transportan por el aire.

4. Seguridad de las máquinas

Mantenga el CNC conectado a tierra y evite los aparatos electrónicos abiertos cerca de la zona de trabajo. Algunos maquinistas utilizan un sistema de nebulización ligera o "corte húmedo" para atrapar el polvo y mantener el material frío.

Cómo elegir las fresas adecuadas

Las brocas de carburo sólido para corte de grafito de carbono y fibra de carbono de Amana Tools® están diseñadas para producir un fallo mínimo en materiales compuestos, como separación de capas y pérdida significativa de tenacidad mecánica. Su serie de corte de materiales compuestos está diseñada específicamente para materiales como fibra de carbono, fibra de vidrio y G10.

Fresas de fibra de carbono y composite Amana Tool

Algunas de las opciones más populares son las brocas de carburo macizo de corte descendente con patrón de diamante y las brocas de inserción de cuchilla reemplazable. Estas herramientas están diseñadas para cortar fibras limpiamente, resistir el calor y mantener el filo durante más tiempo que las brocas genéricas.

¿Qué tipo de broca debe utilizar?

- Brocas de corte descendente: Lo mejor para láminas finas de fibra de carbono o cuando el acabado de la superficie superior es crítico. Empujan las fibras hacia abajo y reducen el deshilachado del borde superior.

- Fresas de corte ascendente: Proporcionan una mejor evacuación de la viruta pero pueden deshilachar la capa superior - ideal para cortes más profundos o cuando la superficie superior será recortada posteriormente.

- Fresas de compresión: Combinan filos ascendentes y descendentes para proporcionar un filo limpio en ambos lados, ideal para cortes pasantes.

- Brocas de inserción: Para los talleres de producción, las brocas de inserción con cuchillas de metal duro reemplazables ofrecen una larga vida útil y rentabilidad.

Consejos de corte para resultados limpios

- Utilice brocas bien afiladas. Incluso las brocas para materiales compuestos se desafilan más rápido en fibra de carbono.

- Alta velocidad del husillo, avance moderado. Alrededor de 18.000-20.000 RPM con una carga de viruta conservadora es un buen punto de partida; ajústelo a su máquina y material.

- Realice pasadas poco profundas. Múltiples pasadas ligeras reducen la tensión en el laminado y ayudan a prevenir la delaminación.

- Asegure la pieza de trabajo. Las mesas de vacío funcionan mejor; cualquier movimiento o vibración arruinará el acabado.

- Evite las fresas convencionales. Las fresas de metal duro estándar se desafilan rápidamente, se calientan y trituran las fibras.

- Pruebe primero con chatarra. Los pequeños cortes de prueba ayudan a ajustar la velocidad y la profundidad antes de mecanizar la pieza final.

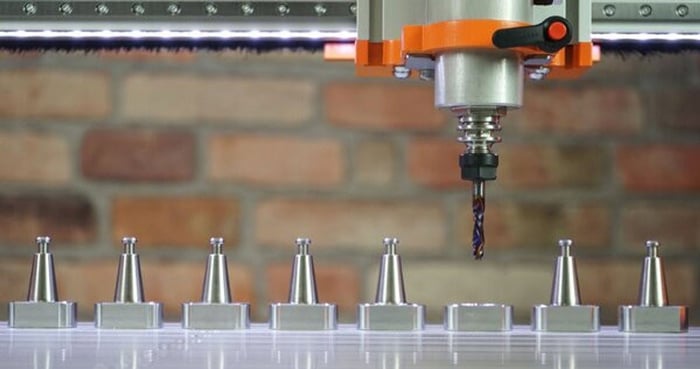

Ejemplo de configuración

Máquina: Fresadora CNC de tamaño medio con husillo rígido

Material: placa de fibra de 2 mm

Fresa: fresa de composite de corte descendente (por ejemplo, Amana Tool 464110)

Velocidad del husillo: ~19.000 RPM

Velocidad de avance: ~1.200 mm/min

Profundidad de pasada: ~0,5 mm

Resultado: bordes lisos, mínima pelusa, sin quemaduras de resina. Tras el corte, un rápido lijado manual con grano fino o una lima de diamante deja el canto listo para el encolado o el barnizado.

Acabado y limpieza

Después del mecanizado:

- Limpie la superficie con alcohol isopropílico para eliminar el polvo y los residuos.

- Lije ligeramente los bordes si es necesario, pero evite sobrecalentar el material.

- Elimine el polvo de carbón de forma segura: nunca lo barra al aire libre ni utilice aire comprimido para limpiarlo.

Conclusión

Cortar fibra de carbono en un CNC puede ser intimidante, pero con las brocas de corte de composite adecuadas de Amana Tool, el control de polvo adecuado y los parámetros de corte ajustados, obtendrá resultados de calidad profesional con un aspecto tan bueno como su rendimiento.

Estas brocas están diseñadas para hacer frente a los desafíos únicos de la fibra de carbono, manteniéndose afiladas durante más tiempo, cortando de forma más limpia y manteniendo su taller más seguro.

¿Listo para equipar su taller? Explore la gama completa de fresas de composite de Amana Tool en ToolsToday para encontrar la fresa adecuada para su próximo proyecto.

Preguntas frecuentes

¿Se puede cortar fibra de carbono con una fresadora CNC normal?

Sí, siempre que utilice las fresas adecuadas y un sistema de recogida de polvo apropiado. La fibra de carbono es extremadamente abrasiva, por lo que sólo debe utilizar brocas de carburo sólido de corte compuesto o con patrón de diamante específicamente diseñadas para fibra de carbono o CFRP. Las brocas de carburo normales se desafilarán rápidamente y pueden causar deshilachado o delaminación.

¿Cuál es la mejor fresa para cortar fibra de carbono?

Las mejores opciones son las brocas para materiales compuestos de corte descendente o de compresión, como las brocas con patrón de diamante de Amana Tool o las brocas en espiral recubiertas de Spektra™. Están diseñadas para cortar las fibras limpiamente y resistir el calor y la abrasión causados por la dura superficie de la fibra de carbono.

¿Qué velocidad de husillo y avance debo utilizar?

Un buen punto de partida son unas 18.000-20.000 RPM con una velocidad de avance moderada de 1.000-1.500 mm/min (40-60 pulg/min), dependiendo de la máquina y del grosor del material. Pruebe siempre primero con restos: demasiado lento y sobrecalentará la resina; demasiado rápido y correrá el riesgo de delaminación.

¿Es peligroso cortar fibra de carbono?

Puede serlo. El polvo de carbón es fino, conductor y peligroso de respirar, así que utilice siempre protección respiratoria P100, protección ocular sellada y aspiración activa del polvo directamente en el punto de corte. Evite soplar o barrer el polvo en el aire.

¿Cómo se evitan los bordes deshilachados o ásperos al cortar fibra de carbono?

Utilice una broca compuesta afilada, realice pasadas poco profundas y fije la pieza firmemente con una mesa de vacío o cinta adhesiva. Las brocas de corte descendente o de compresión minimizarán el deshilachado de la superficie superior e inferior, mientras que un ligero lijado posterior puede perfeccionar el borde.

¿Se puede utilizar refrigerante o nebulizador al cortar fibra de carbono?

Sí, una ligera nebulización o el corte en húmedo pueden ayudar a reducir el calor y atrapar el polvo suspendido en el aire. Sin embargo, asegúrese de que el CNC y el sistema de captación de polvo son aptos para el uso en húmedo para evitar riesgos eléctricos.

¿Cómo debe limpiarse el polvo de fibra de carbono?

Utilice una aspiradora HEPA para recoger el polvo directamente de la zona de trabajo. Evite el aire comprimido o el barrido en seco. Limpie las superficies con alcohol isopropílico y elimine el polvo de forma segura para evitar su dispersión o la acumulación de electricidad estática.

¿Funcionan las fresas Amana Tool para otros materiales compuestos además de la fibra de carbono?

Absolutamente. La serie de brocas para corte de materiales compuestos de Amana está diseñada para fibra de vidrio, G10, grafito de carbono y materiales similares: cualquier material compuesto abrasivo en el que el control del calor y la calidad del filo sean fundamentales.

¿Pueden los principiantes en CNC cortar fibra de carbono de forma segura?

Sí, pero empiece poco a poco. Utilice el equipo de seguridad adecuado, realice pasadas ligeras y familiarícese con la configuración de la recogida de polvo antes de pasar a hojas de tamaño completo. Si sigue las directrices de seguridad y configuración de este artículo, tanto usted como su máquina estarán protegidos.