Fresas para la fabricación de muebles. Corte más rápido. Se mantienen lisas.

Índice

- El verdadero cuello de botella: La selección de la broca y el desgaste de la herramienta

- Spektra Brocas espirales de compresión de carburo sólido -- el recubrimiento de nanocompuesto proporciona una mayor vida útil en materiales abrasivos. Especialmente adecuadas para melamina de doble cara o material laminado.

- Brocas de compresión: Cortes rápidos, bordes impecables

- Las espirales de desbaste de metal duro CNC de Amana Tool tienen un diseño rompevirutas único. También disponibles como espirales de desbaste de corte descendente.

- Brocas de desbaste y desbastado: Elimine material, no tiempo

- La fresa CNC con plaquita de carburo macizo para desbaste, aplanado y rectificado viene con cuchillas de plaquita de carburo macizo con cuatro filos de corte, para que pueda girar la cuchilla cuando un lado se desafile, proporcionando el acabado de mayor calidad disponible en herramientas para trabajar la madera.

- Brocas de inserción: Manténgase afilado, reduzca el tiempo de inactividad

- Más allá del corte: Integración de CNC y lijado

- Consejos de alimentación y velocidad para ser constante

- Aumentar el rendimiento, no el tiempo de lijado

- Preguntas frecuentes

Cuando los pedidos de muebles se acumulan, el reto no es encontrar más horas, sino cortar más rápido sin estropear el acabado. En los talleres de producción pequeños y medianos, la velocidad y la calidad de la superficie a menudo parecen un compromiso. Si presiona demasiado su CNC, obtendrá marcas de desgarro, quemaduras o vibraciones que acabarán con su presupuesto de lijado. Si trabaja demasiado despacio, el rendimiento se reduce. La solución empieza con las brocas adecuadas, diseñadas para ofrecer velocidad y precisión.

El verdadero cuello de botella: La selección de la broca y el desgaste de la herramienta

En muchas fábricas de muebles, los retrasos en la producción no se deben a la programación o a los avances, sino a la elección de la herramienta. Las brocas en espiral estándar funcionan bien para trabajos puntuales, pero en una tirada de producción, incluso una pequeña pérdida de filo se traduce en repeticiones y tiempos de inactividad. Utilizar la geometría y el grado de material adecuados puede prolongar la vida útil de la herramienta en 3 veces o más, al tiempo que permite alcanzar velocidades de avance que antes parecían arriesgadas.

Spektra Brocas espirales de compresión de carburo sólido -- el recubrimiento de nanocompuesto proporciona una mayor vida útil en materiales abrasivos. Especialmente adecuadas para melamina de doble cara o material laminado.

Spektra Brocas espirales de compresión de carburo sólido -- el recubrimiento de nanocompuesto proporciona una mayor vida útil en materiales abrasivos. Especialmente adecuadas para melamina de doble cara o material laminado.

Spektra Brocas espirales de compresión de carburo sólido -- el recubrimiento de nanocompuesto proporciona una mayor vida útil en materiales abrasivos. Especialmente adecuadas para melamina de doble cara o material laminado.

Spektra Brocas espirales de compresión de carburo sólido -- el recubrimiento de nanocompuesto proporciona una mayor vida útil en materiales abrasivos. Especialmente adecuadas para melamina de doble cara o material laminado.Brocas de compresión: Cortes rápidos, bordes impecables

Las brocas espirales de compresión son las más utilizadas para tableros contrachapados, melamínicos y chapados, todos ellos elementos básicos en la producción de muebles. Con ranuras de corte hacia arriba y hacia abajo en una sola herramienta, tiran de las virutas hacia el centro, evitando que se rompan por ambas caras. El resultado es un borde nítido directamente de la máquina, listo para el montaje o el acabado.

Para maximizar la velocidad, comience con una velocidad de avance lo suficientemente agresiva como para que la broca corte en lugar de rozar. Mantenga todo el diámetro de la broca en el corte siempre que sea posible; las pasadas de profundidad parcial pueden anular el efecto de compresión. Para la mayoría de las brocas de compresión de 3/8" o 1/2", una carga de viruta de entre 0,006"-0,012" por diente es el punto óptimo para cortes limpios y eficientes.

Las espirales de des baste de metal duro CNC de Amana Tool tienen un diseño rompevirutas único. También disponibles como espirales de desbaste de corte descendente.

Las espirales de des baste de metal duro CNC de Amana Tool tienen un diseño rompevirutas único. También disponibles como espirales de desbaste de corte descendente.

Las espirales de des baste de metal duro CNC de Amana Tool tienen un diseño rompevirutas único. También disponibles como espirales de desbaste de corte descendente.

Las espirales de des baste de metal duro CNC de Amana Tool tienen un diseño rompevirutas único. También disponibles como espirales de desbaste de corte descendente.Brocas de desbaste y desbastado: Elimine material, no tiempo

Para dar forma a componentes de mesas, respaldos de sillas o paneles de madera maciza, las brocas de desbaste ahorran horas. Fresas de desbaste en espiral utilizan bordes dentados para romper las virutas en trozos más pequeños, eliminando los residuos más rápidamente y manteniendo la fresa más fría. Están diseñadas para eliminar grandes cantidades de material (entre un 40% y un 60% más rápido que las espirales estándar) sin sacrificar la calidad del acabado final.

Combine una broca de desbaste con una de acabado utilizando una broca estándar de corte ascendente o de compresión. La combinación proporciona velocidad y perfección de la superficie, lo que resulta ideal para la fabricación anidada o el mecanizado de paneles gruesos de madera dura.

La fresa CNC con plaquita de carburo macizo para desbaste, aplanado y rectificado viene con cuchillas de plaquita de carburo macizo con cuatro filos de corte, para que pueda girar la cuchilla cuando un lado se desafile, proporcionando el acabado de mayor calidad disponible en herramientas para trabajar la madera.

La fresa CNC con plaquita de carburo macizo para desbaste, aplanado y rectificado viene con cuchillas de plaquita de carburo macizo con cuatro filos de corte, para que pueda girar la cuchilla cuando un lado se desafile, proporcionando el acabado de mayor calidad disponible en herramientas para trabajar la madera.

La fresa CNC con plaquita de carburo macizo para desbaste, aplanado y rectificado viene con cuchillas de plaquita de carburo macizo con cuatro filos de corte, para que pueda girar la cuchilla cuando un lado se desafile, proporcionando el acabado de mayor calidad disponible en herramientas para trabajar la madera.

La fresa CNC con plaquita de carburo macizo para desbaste, aplanado y rectificado viene con cuchillas de plaquita de carburo macizo con cuatro filos de corte, para que pueda girar la cuchilla cuando un lado se desafile, proporcionando el acabado de mayor calidad disponible en herramientas para trabajar la madera.Brocas de inserción: Manténgase afilado, reduzca el tiempo de inactividad

Las fresas de inserción son las mejores aliadas de los talleres de producción. En lugar de afilar o sustituir toda la fresa, basta con girar o cambiar las plaquitas de metal duro. Esto mantiene la geometría del filo constante y la máquina en funcionamiento. Las fresas de inserción son ideales para el corte de grandes volúmenes de MDF, maderas duras y paneles compuestos, donde incluso un pequeño desgaste puede ralentizar los tiempos de ciclo.

Más allá de la comodidad, las brocas de inserción ofrecen una mejora de rendimiento cuantificable: calidad de acabado constante y reducción de la carga del husillo. Son especialmente valiosas para piezas repetitivas como puertas de armarios, frentes de cajones y componentes de tableros de mesa.

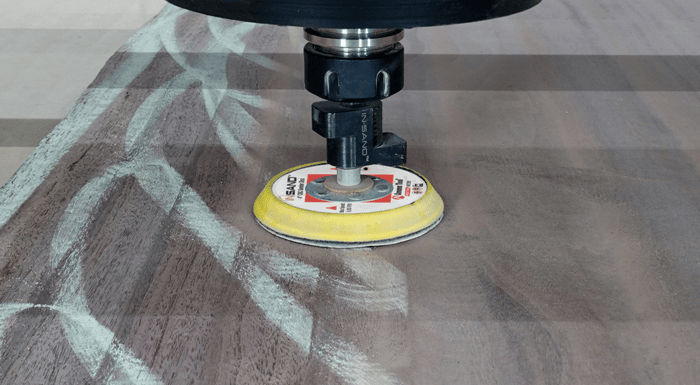

Más allá del corte: Integración de CNC y lijado

La velocidad y el acabado no sólo dependen de lo rápido que corte, sino también de lo poco que tenga que lijar. Aquí es donde entra en juego la lijadora CNC orbital no aleatoria con equilibrio dinámico IN-SAND de Amana Tool. Diseñada específicamente para uso CNC, esta herramienta cuenta con una almohadilla de 4″ de diámetro, un vástago de ½″ y un movimiento orbital no aleatorio que proporciona un acabado uniforme y suave en grandes superficies.

Integrar el lijado CNC en su flujo de trabajo de fresado significa que puede reducir el tiempo de lijado manual y mantener un alto rendimiento: el movimiento preciso garantiza unas marcas de remolino mínimas, lo que ayuda a mantener una calidad de acabado superior incluso a medida que aumenta la producción.

Consejos de alimentación y velocidad para ser constante

- Controle la carga de viruta: no se fíe sólo de los gráficos de velocidad del husillo. Las herramientas desafiladas o los problemas de sujeción por vacío pueden crear un exceso de fricción.

- Utilice el corte ascendente siempre que sea posible: produce una superficie más limpia en la mayoría de los materiales, especialmente en las maderas duras.

- Mantenga las brocas limpias: la acumulación de resina actúa como un filo romo. Utilice regularmente un limpiador de brocas específico.

- Equilibre las pasadas: desbaste y acabado, en lugar de un corte profundo. A menudo ganará velocidad y calidad de acabado.

Aumentar el rendimiento, no el tiempo de lijado

Aumentar la producción no siempre significa actualizar el CNC o añadir un turno. A menudo significa actualizar su estrategia de herramientas. Las espirales de compresión, las brocas de desbaste y las herramientas de inserción desempeñan un papel importante en la rapidez de los cortes, la limpieza de los bordes y la suavidad de los acabados. Tanto si fabrica 50 mesas a la semana como 500 paneles para armarios, la elección de las brocas adecuadas puede marcar la diferencia entre las horas extraordinarias y la puntualidad.

Explore las brocas para fresadora y las brocas para fresadora CNC de Amana Tool, diseñadas para la producción de muebles - diseñadas para ayudarle a cortar más rápido y sin problemas.

Preguntas frecuentes

¿Cuáles son las mejores fresas para la fabricación de muebles?

Las mejores fresas para la fabricación de muebles son las fresas espirales de compresión, las fresas CNC de inserción y las fresas espirales de desbaste. Las brocas de compresión proporcionan bordes superiores e inferiores limpios en paneles chapados o laminados. Las brocas de inserción reducen el tiempo de inactividad con cuchillas de metal duro reemplazables, y las brocas de desbaste eliminan material rápidamente manteniendo la herramienta fría y eficiente. Juntas, le ayudan a aumentar el rendimiento sin sacrificar el acabado superficial.

¿Cómo puedo aumentar la velocidad de fresado CNC sin perder calidad de acabado?

Para cortar más rápido sin dañar la superficie, utilice brocas afiladas de calidad de producción y adapte la velocidad de avance a la carga de virutas. Las brocas sin filo o los avances lentos provocan calor y desgarros. Comience con una pasada de desbaste para eliminar la mayor parte del material y, a continuación, realice una pasada ligera de acabado con una espiral de compresión o de corte ascendente. Mantener las brocas limpias y equilibradas también ayuda a mantener acabados de alta calidad a velocidades de producción.

¿Cuál es la ventaja de utilizar fresas de inserción en la fabricación de muebles?

Las fresas con plaquitas tienen plaquitas de metal duro reemplazables que pueden girarse o cambiarse cuando están desafiladas. Esto elimina la necesidad de afilado, mantiene la geometría de corte constante y reduce drásticamente el tiempo de inactividad. Son ideales para piezas de gran volumen, como puertas de armarios o tableros de mesa, ya que ofrecen un acabado de superficie liso y uniforme en largas tiradas de producción.

¿Cómo mejora la producción de muebles la lijadora CNC IN-SAND de Amana Tool?

La lijadora CNC IN-SAND Dynamically Balanced de Amana Tool integra el lijado directamente en su flujo de trabajo CNC. Alisa las superficies inmediatamente después del fresado, reduciendo el lijado manual y mejorando la consistencia. Su acción orbital no aleatoria y su diseño equilibrado minimizan las marcas de remolino, por lo que los componentes de los muebles salen de la máquina con una superficie lista para el acabado, ahorrando tiempo y mano de obra.

¿Qué velocidades de avance debo utilizar para las fresas CNC al cortar paneles de muebles?

Las velocidades de avance varían según el material y el tamaño de la broca, pero como pauta general, la mayoría de los fabricantes de muebles obtienen excelentes resultados con cargas de viruta de entre 0,006″ y 0,012″ por diente cuando utilizan brocas de compresión de 3/8″ o 1/2″. Comience siempre de forma conservadora y, a continuación, ajuste el avance y la velocidad del husillo a la vez para mantener el grosor de viruta adecuado. El objetivo es cortar limpiamente -no quemar ni frotar- para obtener un resultado más rápido y suave.